Showing 25–36 of 39 results

Material Test Frames – Dual Column

The MMD Series are dual column, table-top testing systems operated using our L3 Material Test software. These systems are ideal for a variety of applications including plastics, composites, metals, rubber, automotive/aerospace components, medical devices, adhesives, foams, film and more. Perform tensile, compressive, cyclic, flexural, shear and other types of testing. Three model load capacities are available: 10kN, 30kN and 50kN. Testers feature a granite base with all-metal columns and pre-loaded ball screws for excellent extension control and precision measurements. Magnetic travel limits are adjustable to prevent over travel situations. Testers are inherently stiff and we include stiffness compensation correction to eliminate all errors due to mechanical deflection in the entire load string. Communications to the all-in-one touchscreen desktop computer is via USB. Frames feature digital and analog I/O and support for two extensometers. Data sampling is selectable between 1-2000Hz. MMD test frames may use ULC, MLC or FLC load cell sensors. Sensors are IEEE 1451.4 compliant. Frames may be fitted with optional splinter shield.

Material Testers – Single Column

The MMS Series are single column, table-top testing systems operated using our L3 Material Test software. These systems are ideal for a variety of applications including plastics, composites, metals, rubber, automotive/aerospace components, medical devices, adhesives, foams, film and more. Perform tensile, compressive, cyclic, flexural, shear and other types of testing.

Four model load capacities are available: 500N, 1kN, 2.5kN and 5kN. Testers feature a granite base with all-metal column and pre-loaded ball screws for excellent extension control and precision measurements. Magnetic travel limits are adjustable to prevent over travel situations. Testers are inherently stiff and we include stiffness compensation correction to eliminate all errors due to mechanical deflection in the entire load string.

Communications to the all-in-one touchscreen desktop computer is via USB. Frames feature digital and analog I/O and support for two extensometers. Data sampling is selectable between 1–2000Hz. MMS test frames may use ULC, MLC or FLC load cell sensors. Sensors are IEEE 1451.4 compliant. Frames may be fitted with optional splinter shield.

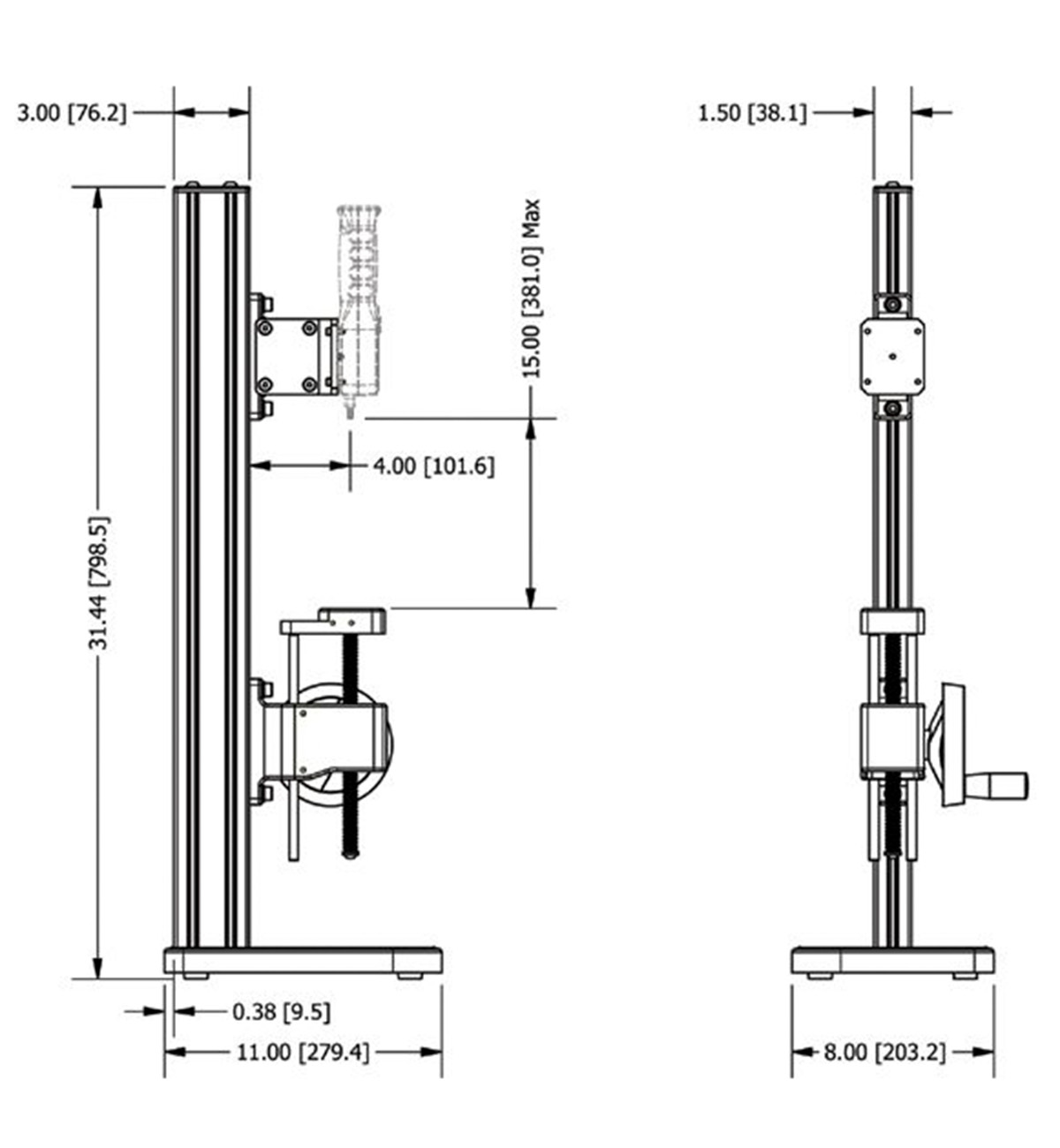

The Chatillon MT Series manual test stand is a flexible, easy-to-use solution for force measurement. It comes in two versions: the MT150 and the MT500.

This manual test stand is ideal for tensile testing, compression testing, peel, and flexural testing.

The MT Series manual test stands are often used with the DF Series digital force gauges to check the force necessary to depress a button, or with the LG/DG mechanical gauge to perform low range pull tests at the end of a production line where caps are placed on spray bottles. These test stands are commonly used to test the force in the Packaging Industry as for folding cardboard boxes into shape.

The MT Series test stand comes with:

-

a hook

-

compression plate

-

threaded and eye end type adapters

Gauge mounting hardware is optiona

MTH Manual Tester

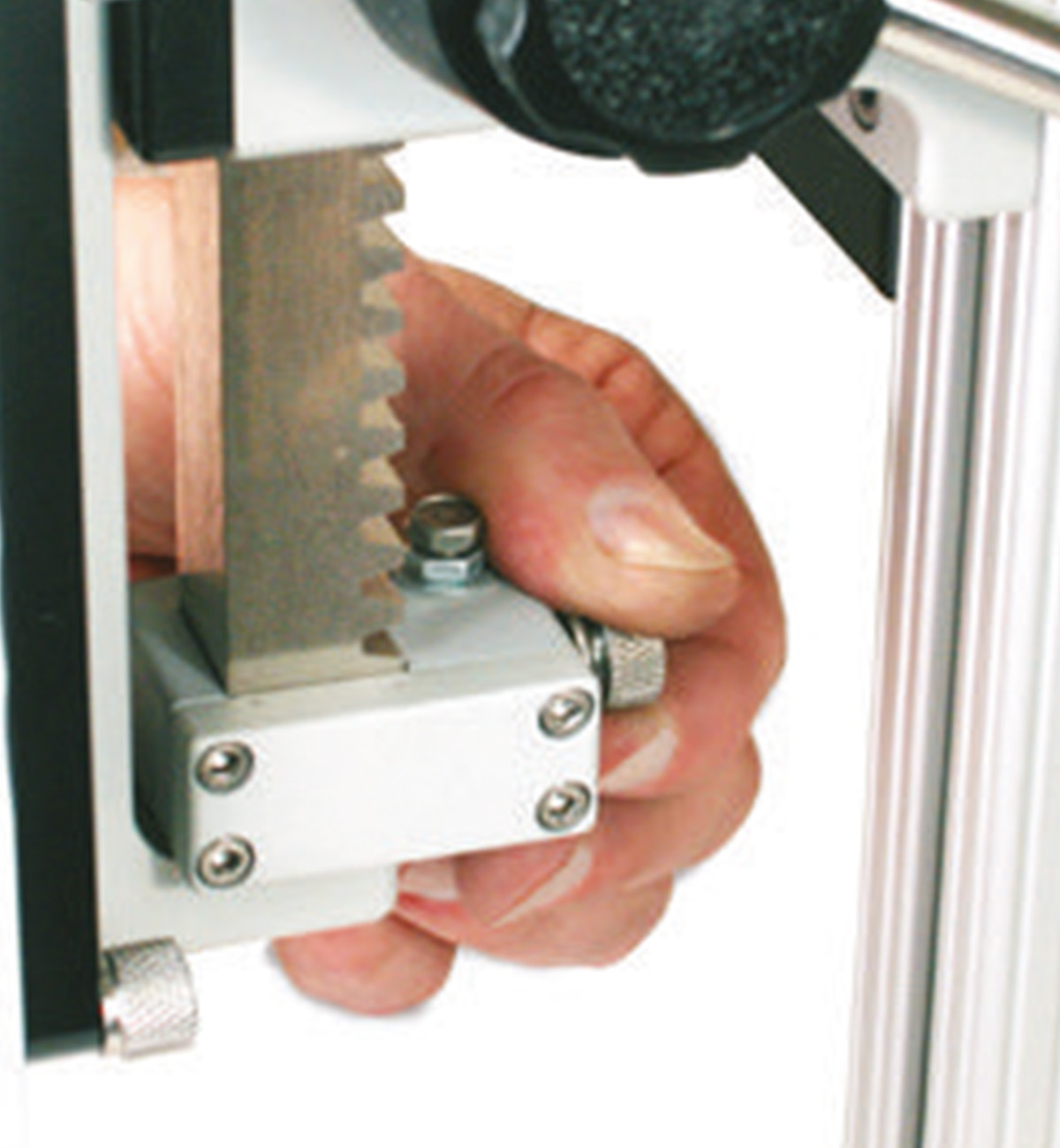

The MTH Manual Tester is a single column, manually-operated force tester. The MTH has a load measurement capacity of 550 lbf (2500N, 250 kgf) and can be used for compression or tensile testing.

The mechanical advantage afforded by the MTH-550’s precision, high-resolution worm gear design lets you test effortlessly. One rotation of the hand wheel positions the crosshead 0.03″ (0.75mm). Total stroke for the MTH-550 is 4″ (102mm). Force measurement is performed using a Starrett digital force gage.

The MTH-550 is an ideal, affordable solution for spring testing. Fit the MTH-550 with a digital force gage and optional digital scale to determine spring rates, initial tension and more.

The hand wheel may be positioned anywhere along the 30″ (762mm) column, and with a 4″ (102mm) throat, large samples can be accurately tested. The base may be permanently affixed to your workbench. Optional gage adapter kits are available for use with non-Starrett force gages. Quick-change clevis adapters let you mount a large selection of Starrett testing fixtures.

MTL-110

The MTL-110 can measure force up to 110lbf (500N, 50kgf). This tester is ideal for component testing and its compact design fits small work spaces. The MTL-110 has a 6″ (152mm) stroke. The tester’s quick-action lever moves the rack and pinion crosshead 3″ (76mm) per revolution. The lever may be positioned anywhere along the 20″ (508mm) column, and with a 6″ (152mm) throat, large samples can be accurately tested. Options include a digital scale for measuring deflection distance. The base adapter adjusts to accommodate different gage models.

The MTL may be equipped with optional legs so that you can test in a horizontal position.

MTL-330

The MTL-330 can measure force up to 330lbf (1500N, 150kgf). This tester can be used for tensile and compression testing applications, and is ideal for spring testing. Fit the MTL-330 with a Starrett digital force gage and optional digital scale to determine spring rates, initial tension and more. The MTL-330 can be easily mounted to your workbench for secure testing.

Like the smaller MTL-110, the quick-action lever moves the rack and pinion crosshead 3″ (76mm) per revolution. The lever may be positioned anywhere on the 30″ (762mm) column, and with a 4″ (102mm) throat, large samples can be accurately tested. Optional gage adapter kits are available for use with non-Starrett force gages.

The MTL may be equipped with optional legs so that you can test in a horizontal position.

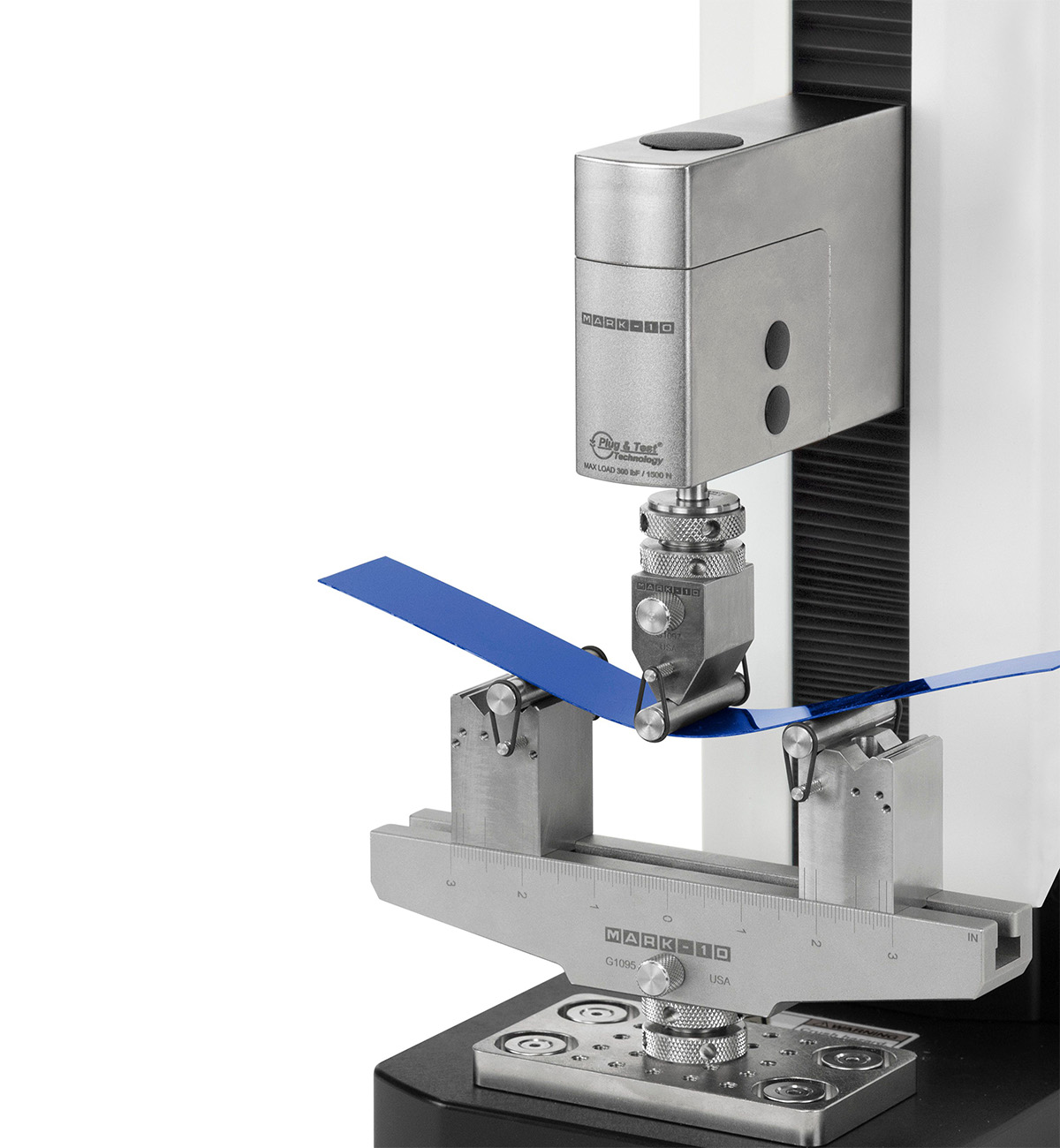

Series F Tension / Compression Test Frames

Series F Tension / Compression Test Frames are engineered for force testing applications up to 1,500 lbf (6.7 kN). Select from a broad range of force sensor capacities and an expansive array of grips and fixtures.

Set up tests, view results, and export data via the integrated EasyMESUR® control panel. Satisfy various test methods through an easy-to-use interface, with a menu of available optional functions and function packages. The system can be tailored to your unique needs and budget, and is easily upgradeable in the field.

Virtually limitless applications

From food packaging to electronics, from consumer products to aerospace manufacturing, Mark-10 force test frames are at home in laboratory and production environments in virtually every industry worldwide.

Virtually limitless applications

From food packaging to electronics, from consumer products to aerospace manufacturing, Mark-10 force test frames are at home in laboratory and production environments in virtually every industry worldwide.

Force Measurement Re-imagined

Series F Tension / Compression Test Frames are engineered for force testing applications up to 1,500 lbf (6.7 kN). Select from a broad range of force sensor capacities and an expansive array of grips and fixtures.

Set up tests, record data, and analyze data via IntelliMESUR® software. From basic tests to multi-step sequencing, IntelliMESUR® is fully integrated with Series F systems. Select from a pre-configured tablet control panel or standalone software for your own Windows device.

Virtually limitless applications

From food packaging to electronics, from consumer products to aerospace manufacturing, Mark-10 force test frames are at home in laboratory and production environments in virtually every industry worldwide.

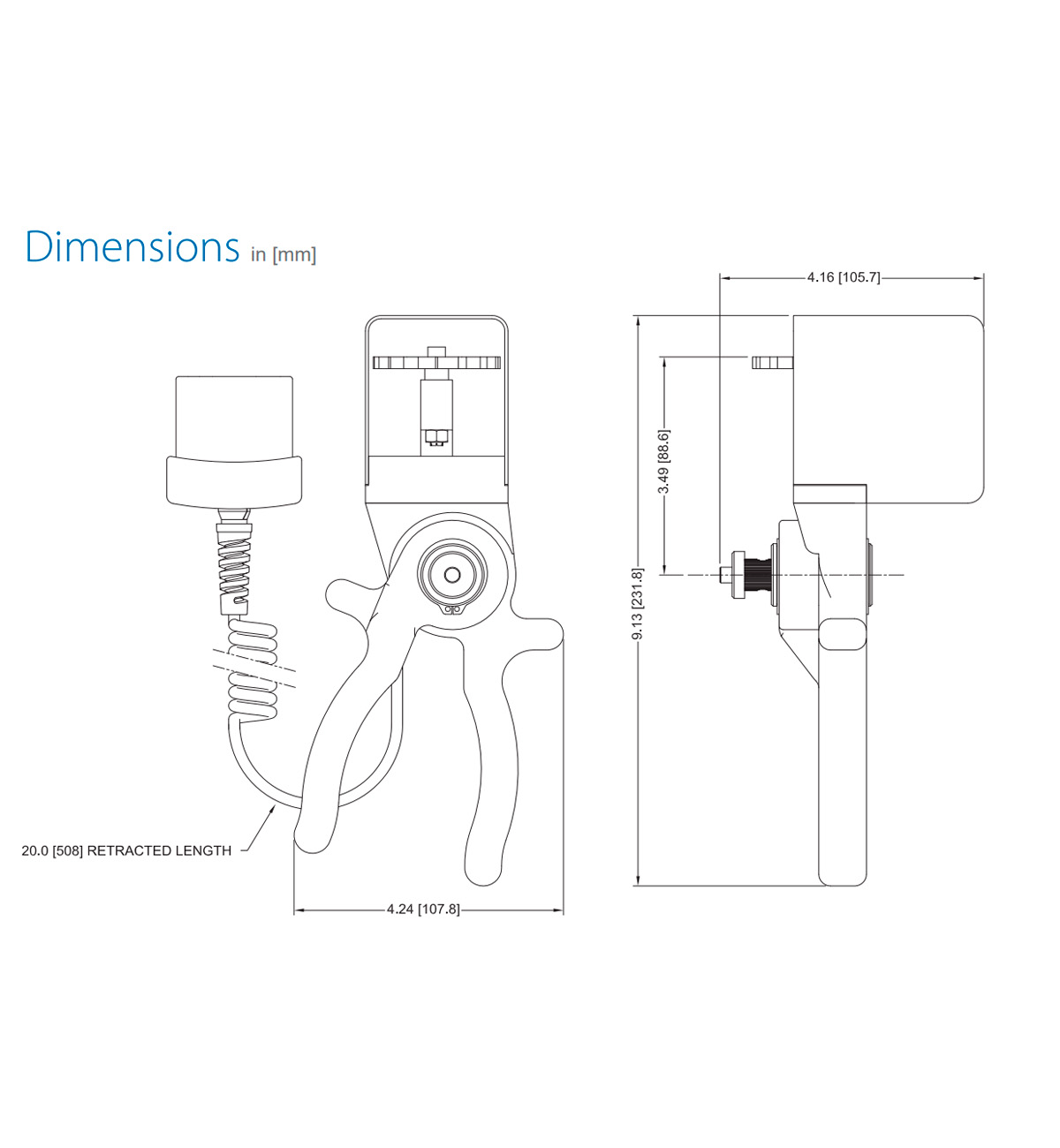

The MR06-200 wire crimp pull sensor is a hand-operated solution for measuring wire crimp pull-off forces. The ergonomic handles and convenient tensioning mechanism make field measurements a breeze for applications up to 200 lbf (1,000 N). Squeeze the handles together to increase tension on the sample until a break occurs. The peak force is recorded by the indicator.

A rotating turret with slots of multiple sizes accommodates a wide range of wire diameters, up to 0.25 in. (6.4 mm).

A combined certificate for the sensor and an indicator is available at time of order, part no. CERT-SI.

Intuitive Effectiveness

The motorized TCM Series from Chatillon offers fast and effective force testing at an affordable price.

The TCM Series features a high frame stiffness, light weight bench top design suitable for both production and laboratory environments.

Force ranges of 100 lbf (500 N) and 350 lbf (1500 N) are available in both 16 in (406 mm) and extended 32 in (812 mm) travel versions.

Select from Chatillon’s wide range of grips and fixtures to use the TCM Series for a wide variety of tests such as:

-

Tension

-

Compression

-

Bending

-

Peeling

-

Adhesion

-

Insertion and extraction

The lever operated TSA750 is ideal for quick-action testing of up to 750 lbf (3.75 kN) of tensile or compressive force. Made of rugged components, this test stand is durable enough for the factory floor, yet precise enough for laboratory environments. The loading lever can be positioned in 30° increments and the adjustable precision ground rack and pinion mechanism assures smooth, precise motion through 6 in. of travel.

The test stand includes adjustable travel stops and a frictional low force brake. It is available in vertical and horizontal orientations. Use this test stand with Mark-10 force gauges and gripping fixtures to create a complete push/pull testing system.

The lever-operated TSB100 test stand is ideal for quick-action tensile testing and compression testing of up to 100 lbf (500 N) of force. Constructed of rugged components, this test stand is durable enough for the factory floor, yet precise enough for laboratory environments.

The TSC1000 test stand is ruggedly built for testing up to 1,000 lbf (5 kN) of compression or tension force. A large hand wheel requires little effort, even at high loads, and a precision Acme screw and nut ensures smooth operation over time. The stand includes a loading table with threaded holes for fixture or grip mounting and a solid metal base (TSC1000) contains a storage pocket and holes for bench mounting. Available in vertical and horizontal configurations.