Showing 13–24 of 56 results

The new FG-3000 Series digital force gaugesare the choice for simple, cost-effective tension and compression testing. Combining one of themost compact housings, yet maintaining a large back-lit LCD,these units were designed to fit perfectly in the hand for ease ofuse. The multi-language FG-3000’s provide menu programmingfor intuitive set-up of the instrument to your desired requirements.Three modes of operation are selectable: Track mode displayslive readings, Peak mode records the maximum reading sensedduring the test, and Pre-set mode which activates user definedhigh and low limit set points. The programmable limits provide aquick visual and audible indication if a test passes or fails. In addition, a comparator output enables integration of the instrumentinto your quality system for repetitive testing such as on production lines.

Digital Force Gauges with 180° reversible display & dual labeled keypad forboth push, pull applications.The Series FGEXY Digital Force Gauges combine a rugged, ergonomic and compact design with exceptional accuracy to provide a solid forcetesting instrument. These instruments are utilized in a variety ofapplications such as, incoming quality inspection, finished goodstesting, R&D or almost any portable or force stand testing requirement.Simple one button adjustment alters units, while pressing thepeak button quickly produces the highest recorded value duringthe test. The 180° reversible display combined with the adjustableforce direction and dual labeled keypad enable the FGE-XY toexcel in both compression and tension applications in any direction. Models are available from 0.5 lbs to 200 lb ranges providinga large offering for various testing requirements.

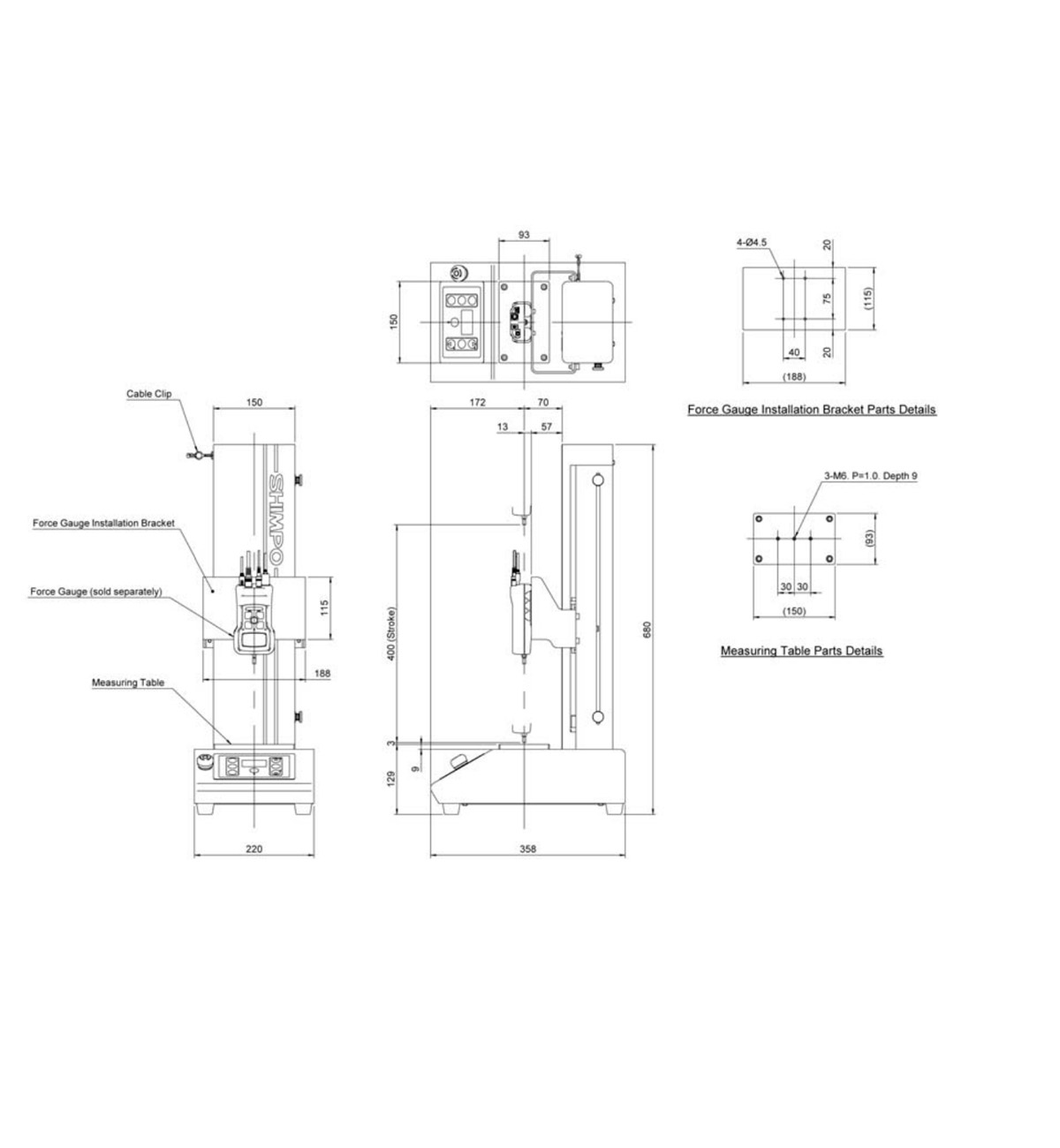

Shimpo’s manual test stands offer the ability to obtain accurate, consistent results without the high cost of a motorized system.

Our lever operated stands are ideal for rapid testing applications and the hand wheel stands are excellent for applications where more precise control is necessary.

Both the lever and the hand wheel stands are available in various capacities and can ensure accurate, consistent test results with the addition of a Shimpo Instruments digital or mechanical force gage.

Nearly all manufacturers’ gauges are compatible with Shimpo’s test stands for incredible versatility. These stands are designed for precision, balance, and durability. Therefore they are perfectly suited for measuring a limitless range of materials such as wire, spring, plastic, paper cord, tubing, glass and composites.

The Series FGS-100E Vertical, Motorized Force Test Stands combined with the Shimpo line of superior quality force gauges, create a complete force measurement system capable of handling the most precise testing applications.

The test stand’s all steel construction makes them remarkably rugged while performing with precision, providing the reliability to tackle a multitude of applications.

The FGS-100E’s possess simplified operation with their 7 button key-pad and emergency stop button, eliminating lengthy training typical of similar test stands. With four modes of operation (manual, jog, single cycle, continuous) various single tests or repetitive tests can be achieved and selected with the push of a button.

The user can quickly change the speed units displayed on the LCD from mm/min to inches/min to satisfy their test requirement or preference. With manually adjustable high and low stop limits, the test stands are designed for minimal time necessary to adjust for the next test. The FGS-100E motorized stands have a capacity rating of 110 lbs (50 kgf) in either fast [0.78-23.60 in/min (20-600 mm/min)] movement operation or slow speed [0.23-7.00 in/min (6-180 mm/min)] operation models. When connected to a Shimpo FGV Force Gauge, the gauge’s programmable overload setting is communicated to the test stand, allowing the stand to stop at the overload set point and prevent potential damage to the gauge’s sensor.

The FGS-VC Series Motorized Force Test Stands are designed to provide accurate and repeatable results for tension, compression, break and cycle performance tests in various applications.

A key feature is a SHIMPO exclusive: a precision made servo gear head and ball screw for precise movement control. The large measurement area plus tall 15.75” (400 mm) travel distance allow large, unique parts to be tested. A precise and consistent 0.40-15.75”/min (10-400mm/min) adjustable speed provides for slow tests or quick cycle load testing.

The simple keypad combined with the intuitive on screen operation guides the user through setting up each test. Users can perform standard tests in several automatic or manually selected modes as well as choose higher-end capabilities with the additional dwell time, adjustable acceleration, plus user-defined tests with up to 5 programmed set points.

The FGS-VC’s are flexible as they can be operated by the keypad or through a PC via the FGT-VC software which includes data collection, graphing and statistical analysis. The FGT-VC software program allows graphing of force versus distance and the ability to compare several tests on a single graph. Another great feature of the FGT-VC is the comparator mode which enables quick decision pass/fail determination, ideal for production line testing.

The FGS-VC’s can be equipped with various gripping and compression fixtures and are compatible with all Shimpo Force Gauges as well as most gauges on the market. These features make the new FGS-VC the ideal push/pull tester for the production line or QC lab.

Digital Force Gauges with 180° reversibledisplay & dual labeled keypad for both push,pull applications. The Series FGV-XY Force Gaugescombine a rugged, ergonomic and compact design to providea complete force testing instrument. These instruments areutilized in a variety of applications such as, incoming qualityinspection, finished goods testing, R&D or almost any portableor force stand testing requirement.

Onboard statistical calculations provide fast access to maximum,minimum, average and standard deviation data. The ToriemonUSB software and USB cable allow further data analysis on aPC. The 1,000 point memory allows for data exporting in realtime or after testing is complete. In addition, the RS-232C andanalog outputs provide the FGV-XY maximum communicationflexibility. Models are available from 0.5 lbs to 200 lb rangesproviding a large offering for various testing requirements. The180° reversible display combined with the adjustable forcedirection and dual labeled keypad enable the FGV-XY to excelin both compression and tension applications in any direction.

Typical applications include wallboard, wire pull, wire crimps,trigger pull, brake pedal, aerospace ceramic, springs, foodripeness, corrugated paper strength, blister pack, medicalcomponent, muscle strength, ergonomic testing, adhesives,syringe plunger, needle sharpness and many more.

Digital Force Testers – FMM Digital Force Testers

FMM Digital Force Testers may be used with L1 software or with a DFC or DFG Digital Force Gage. FMM Digital Force Testers are compact and ideal for high-volume, lean manufacturing production.

FMM testers are available in three capacities: 110lbf (500N), 330lbf (1500N) and 550lbf (2500N). Two travel lengths are available for all capacities: standard travel at 20” (508mm) and extended travel at 30” (762mm). Crosshead speeds are controlled locally and can be set from 0.002 to 40 inch/min (0.05 to 1016mm/min). A high-resolution OLED display shows distance measurements with accuracy better than 20µm (0.0008 inch). Travel limits help prevent load sensor overloading.

The FMM force tester can be controlled using L1 software for limit, cycling, hold and coefficient of friction testing.

The FMM force tester can also be controlled using a DFC digital force gage. The DFC force gage serves as a universal controller where it is used to setup the force tester’s distance limits, crosshead direction and crosshead velocity for a test.

Features

-

Ideal for tension, compression, flexural, cyclic, shear, and friction applications

-

Use with L1 software and 2-in-1 tablet PC or with DFC and DFG force gages

-

Multiple, Easy-to-Use Operating Modes:

-

Manual

-

Automatic

-

Continuous

-

Gage Control (DFC force gage controls FMM tester)

-

Software Control (L1 system control)

-

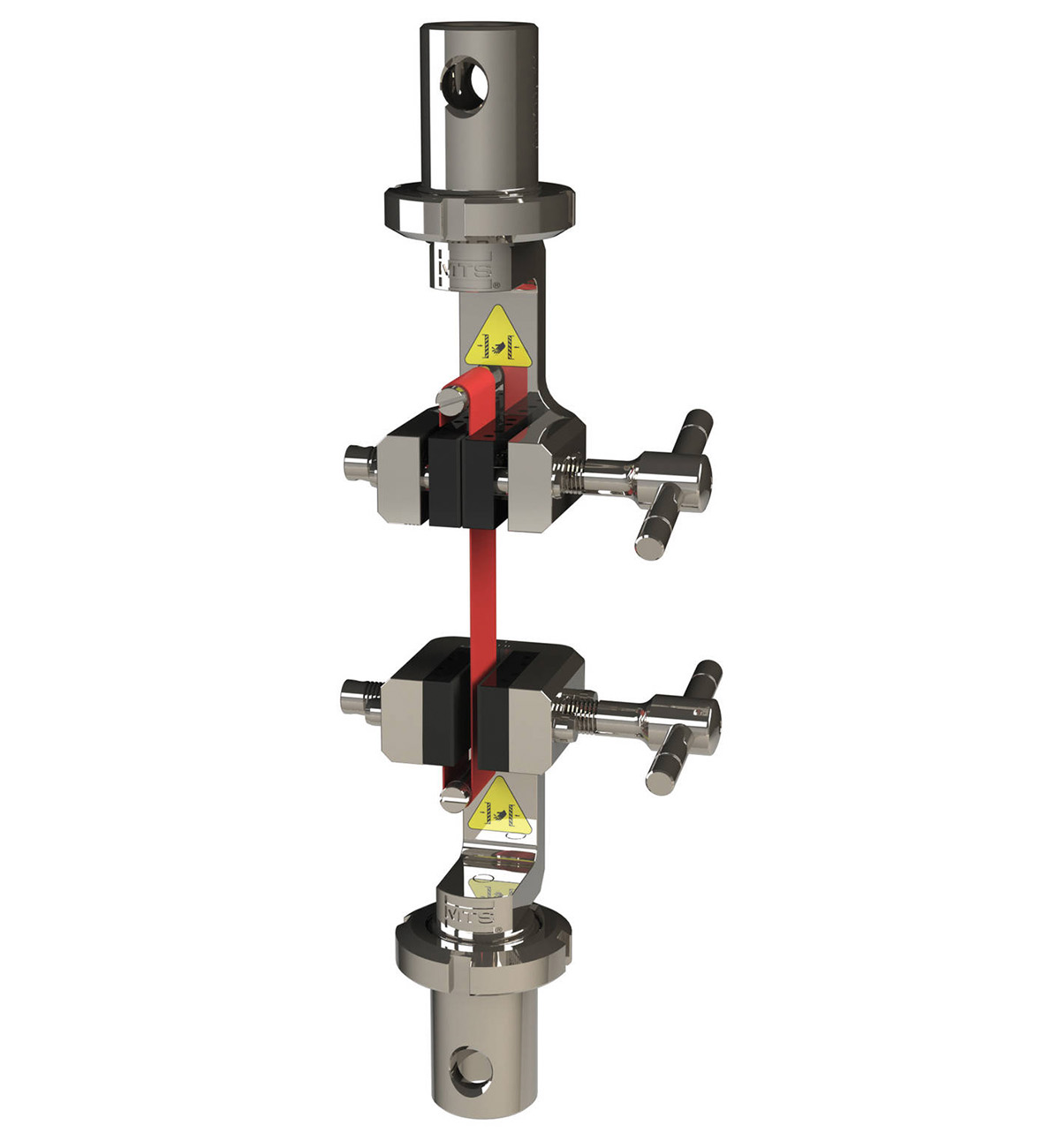

Grips / Fixtures

At Beamar, we offer a wide selection of grips and fixtures designed for various testing applications such as tensile, compression, and flexural testing.

Types of available connections:

- Threaded or female eye connections of 5/8″ or 1.25″ (15.9 mm or 31.8 mm diameter), compliant with the standards of brands such as Lloyd Instruments, Chatillon, and Mark-10.

Multi-brand compatibility:

We also sell equipment —such as test stands, load cells, and force gauges— from these same brands to ensure compatibility with our grips and fixtures.

We also offer adapters that allow mounting our grips and fixtures on universal testing machines.

Not sure which accessory you need?

Our technical team is ready to assist you. We can help you identify the ideal grip, fixture, or adapter for your test stand or specific application.

Contact us for expert assistance in grips, fixtures, and adapters.

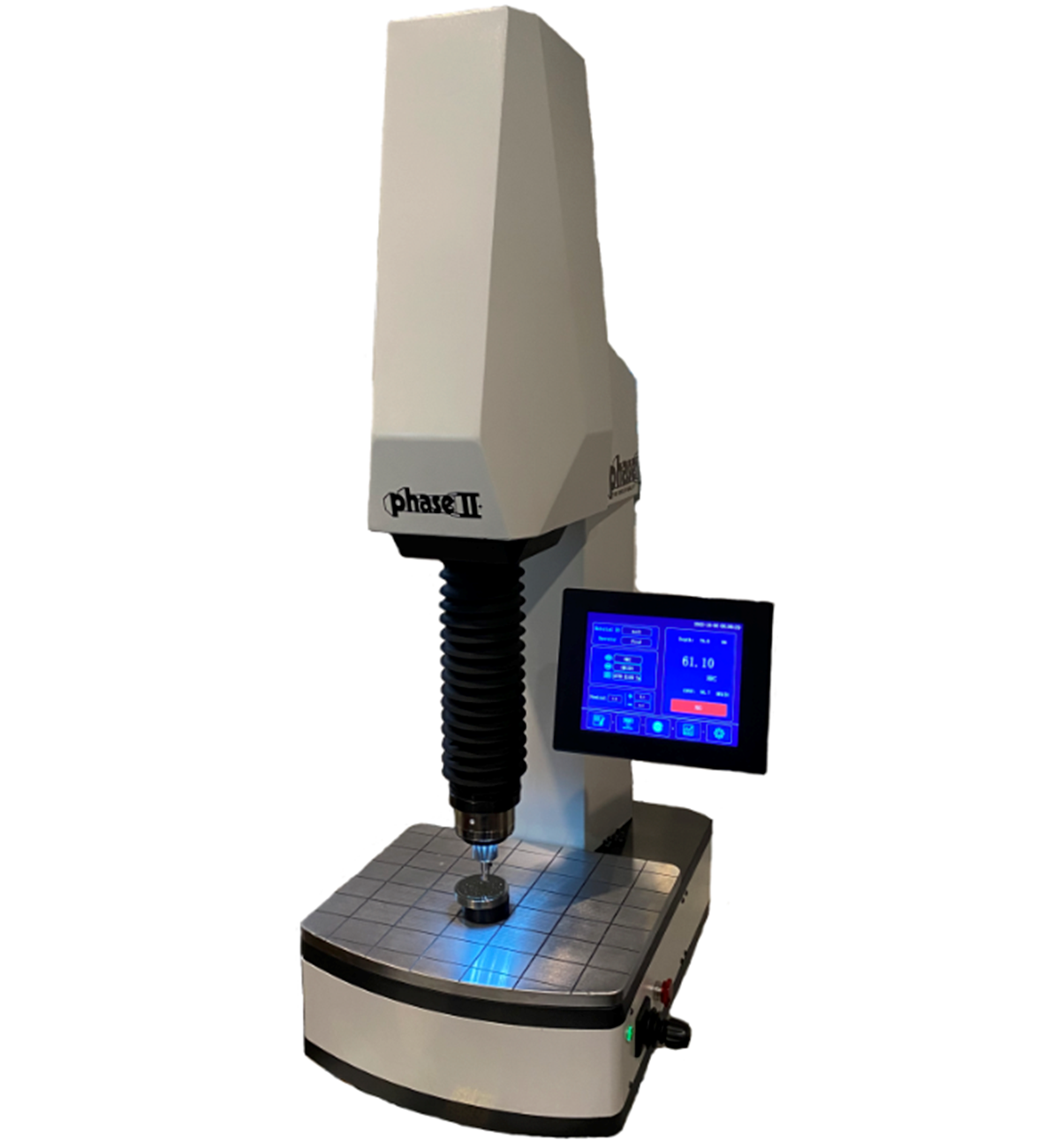

Specialized instruments for measuring a material’s resistance to deformation, essential for ensuring the durability and performance of metals, plastics, and other materials.

- Different scales available (Rockwell, Brinell, Vickers).

- Portable and laboratory models with high precision and repeatability.

- Used in the metalworking, automotive, aerospace, and component manufacturing industries

Not sure which equipment fits your needs?

Consult with one of our specialists for personalized advice. We’ll help you compare options, understand capabilities, and make the best decision.

Talk to a product specialist.

Horizontal Bench-Top Optical Comparator hb400

The HB400 Optical Comparator provides exceptional performance with a 16″ (400mm) diameter viewing screen, LED lighting, and 110lbs (50kg) workstage load capacity. Available with optical and/or video edge detection which removes operator subjectivity in locating edges of parts being measured. A bayonet style lens mounting system accepts a choice of six fixed interchangeable lenses as well as the OV2 Zoom or TOV2 fixed telecentric magnification video camera systems. Motorized stage, fully automatic CNC controls and swing-away lamp house are all optional features. This comparator provides performance previously only available with floor standing models.

HDV Horizontal Digital Video Comparators

The HDV Horizontal Digital Video Comparators combine the best features of a horizontal optical comparator and a vision metrology system. With a rigid steel design, the HDV is configured like a traditional horizontal comparator. The workstages are the same as the Starrett field-proven HB400 bench top and HF750 floor standing comparators, with a 110lb (50kg) and 330 lb (150kg) load capacities respectively. The heart of these systems centers on a uniquely designed interchangeable lens mounting system coupled to a hi-resolution color digital video camera (patent pending). These systems offer zoom optics or a choice of telecentric lenses for micron-level resolution and optical distortion as low as 0.001% for accurate field-of-view (FOV) measurements. Telecentric lenses provide a maximum field of view of up to 3 x 2.5″ (76.5 x 64mm). Stage movement can be related to the imported file allowing part comparison up to 12″ (300mm) on the HDV300, 16″ (400mm) on the HDV400, and up to 20″ (500mm) on the HDV500.

The HDV systems house a powerful 64-bit PC, which runs MetLogix™ M3 Metrology software. With M3 software, DXF CAD files can be imported and 2D “Go-No-Go” digital overlays can be developed directly from the CAD files. Video edge detection (VED) allows real-time interaction of the imported file with the video image of the part being inspected. Productivity, speed and accuracy are all enhanced. HDV300 and HDV400 systems are available in manual or CNC control, while the HDV500 CNC control is standard.

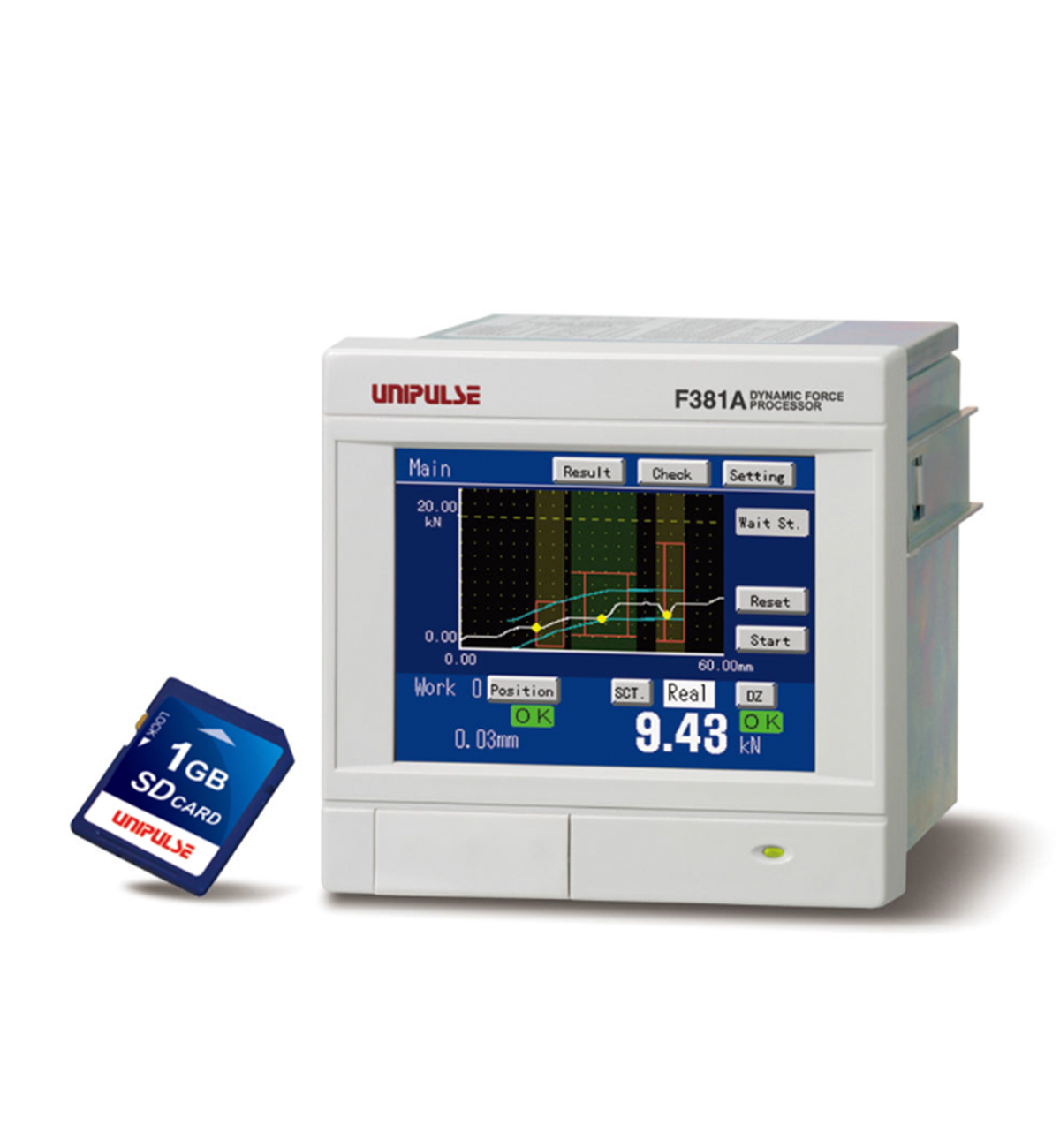

Indicators, displays, and densimeters are equipment designed to visualize and process measurement data clearly, precisely, and in real-time. They serve as the interface between sensors and the user, allowing for the interpretation of critical results for process control, parameter verification, and information traceability.

At Beamar, we have a wide variety of brands and models that adapt to different industrial and laboratory environments, ensuring that each client has the most suitable solution for their specific needs.